2026 Best Stainless Steel Woven Wire Mesh Options Explained?

In the world of industrial materials, stainless steel woven wire mesh plays a crucial role. Experts agree on its versatility and strength. John Smith, a leading figure in the wire mesh industry, once stated, "Stainless steel woven wire mesh is unmatched for durability and reliability." This statement captures the essence of its importance.

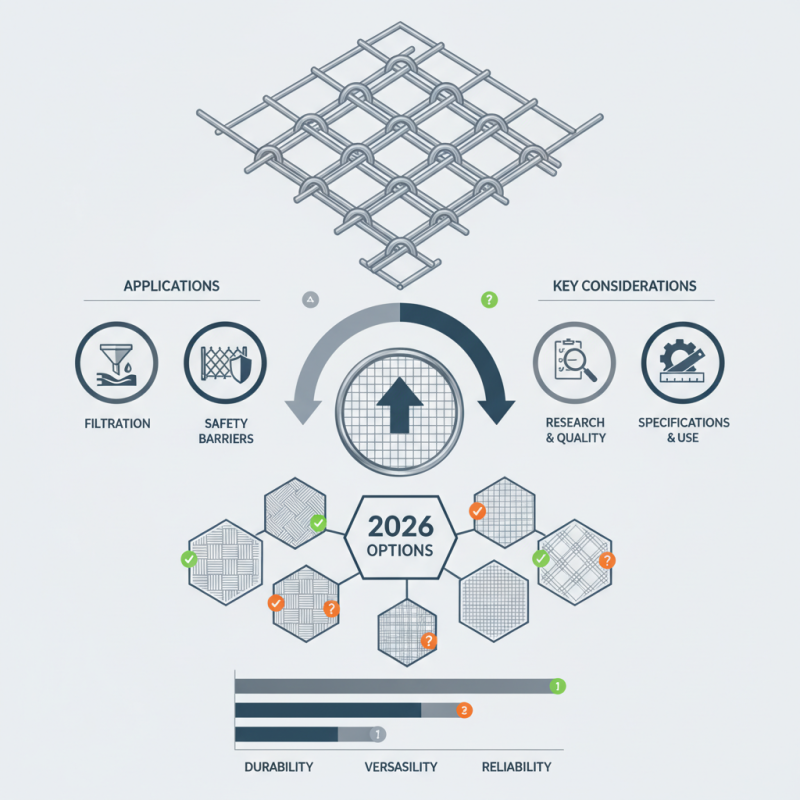

When choosing from the myriad of options available, one must consider specific uses. Some stainless steel woven wire meshes excel in filtration, while others work wonderfully for safety barriers. This variety often makes decision-making overwhelming. Quality varies widely; not every product labeled as "stainless steel" meets industrial standards. Prospective buyers need to research carefully.

Despite its many advantages, users occasionally find challenges in sourcing the right type. Mismatched specifications can lead to disappointing results. It’s essential to identify the precise application before making a selection. In 2026, the best options may still require thoughtful evaluation and greater awareness of manufacturers' claims.

Understanding Stainless Steel Woven Wire Mesh: A Comprehensive Overview

Stainless steel woven wire mesh is known for its durability and versatility. It is often used in various industries, including construction, food processing, and filtration. According to a market report, the global stainless steel woven wire mesh market is expected to grow significantly, driven by high demand in food and pharmaceutical sectors.

One critical factor in selecting woven wire mesh is the type of stainless steel used. Common grades include 304 and 316, each offering different corrosion resistance. Grade 316 is preferable in harsh environments, where chlorides are present. The mesh can withstand high temperatures and is relatively easy to clean. However, some buyers overlook these specifications and may end up with unsuitable materials.

Tips: Always consider your application. The wire diameter and mesh size greatly impact the product's performance. It’s essential to balance strength with flexibility, depending on your needs. Incomplete understanding of your requirements may lead to poor choices and wasted resources.

When sourcing mesh, assess the vendor’s quality assurance processes. Inspecting samples can also reveal any manufacturing inconsistencies. Skipping this step could result in defects affecting your project. Remember that minor imperfections might significantly impact the effectiveness of your mesh in real-world applications.

2026 Best Stainless Steel Woven Wire Mesh Options Explained

| Type | Aperture Size | Wire Diameter | Material Grade | Application |

|---|---|---|---|---|

| Plain Weave | 1.0 mm | 0.3 mm | 304 | Filtration |

| Twill Weave | 0.5 mm | 0.4 mm | 316 | Chemical Processing |

| Dutch Weave | 0.2 mm | 0.5 mm | 304 | Food Processing |

| Leno Weave | 3.0 mm | 1.0 mm | 316L | Cement Industry |

| Hybrid Weave | 2.0 mm | 0.6 mm | 430 | Mining |

Key Benefits of Using Stainless Steel Woven Wire Mesh in Various Applications

Stainless steel woven wire mesh offers numerous benefits across various applications. Its strength and durability make it ideal for industries like construction and agriculture. This type of mesh resists corrosion, ensuring a longer lifespan. It can withstand harsh environments without losing its integrity, making it a reliable choice.

In food processing, stainless steel woven wire mesh is essential. It does not absorb contaminants, ensuring hygiene standards are met. Workers prefer this material because it's easy to clean. However, over time, even the best mesh can show signs of wear. Regular inspections can prevent issues before they arise.

*Tip:* When selecting woven wire mesh, consider the wire gauge. A thicker wire can enhance strength but may reduce flexibility. Balance is key.

Another advantage is its versatility. This mesh can be used in filtration, sieving, and decorative applications. The aesthetic appeal of woven wire can enhance architectural designs. Yet, not all designs suit every project. It's important to reflect on the functional and visual aspects.

*Tip:* Always test a small sample before full installation. It helps identify any unforeseen problems early on.

2026 Best Stainless Steel Woven Wire Mesh Options

Types of Stainless Steel Woven Wire Mesh: Materials and Specifications

Stainless steel woven wire mesh is widely used across various industries, showcasing its versatility and strength. The main materials often include 304 and 316 stainless steel. 304 stainless steel is more affordable and resistant to corrosion, making it a popular choice. 316 stainless steel offers better resistance to harsh environments, especially in marine applications. According to a market report by Grand View Research, the global stainless steel mesh market is projected to reach USD 3.1 billion by 2027, highlighting rapid industry growth.

Different specifications cater to various needs. The diameter of the wire, the weave pattern, and mesh size can significantly affect performance. For instance, a finer mesh size is suitable for filtration applications. However, users may overlook that finer meshes can reduce airflow. This can lead to inefficiencies in specific setups. The balance between mesh size and strength is crucial for optimal performance. A study published in the Journal of Materials Science indicates that improper selection can lead to premature failures in industrial applications.

Additionally, different types of weaves, such as plain weave and twill weave, serve distinct purposes. Plain weave is more common and simple but may lack flexibility. Twill weave, while offering greater flexibility, can be more complex to produce. Understanding these specifications can be overwhelming, and mistakes are easy to make. The right choice often requires careful consideration of both the application and the environment.

Factors to Consider When Selecting Stainless Steel Woven Wire Mesh Options

When selecting stainless steel woven wire mesh options, several factors come into play. The wire diameter and mesh opening size are crucial. Smaller openings provide better filtration, while larger ones allow for greater airflow. Each project has unique requirements that influence these choices. Consider the application carefully. A miscalculation here could lead to inefficiencies.

Durability is another key aspect. Stainless steel offers strength and corrosion resistance. However, not all grades are equal. Higher grades might be necessary for certain environments. Think about where the mesh will be used. Whether it is indoors or outdoors, exposure to elements can impact performance. Testing different grades might reveal surprising results.

The aesthetics of the woven wire mesh matter too. The pattern and finish can enhance or detract from a design. Sometimes, it’s easy to overlook these aspects, focusing only on functionality. Finding the right balance requires careful thought. This process might feel cumbersome, but exploring options will lead to better decisions. A well-chosen mesh not only performs well but also adds to the overall appeal.

Maintenance and Care Tips for Long-Lasting Stainless Steel Woven Wire Mesh

Maintaining stainless steel woven wire mesh requires regular attention. Cleaning is vital for its longevity. Use mild detergent and warm water. Avoid harsh chemicals that can corrode the surface. A gentle scrub with a non-abrasive sponge works wonders. Rinse with fresh water to eliminate any soap residue.

Inspect the mesh periodically for signs of wear. Check for rust or discoloration which can indicate underlying issues. Address any damage immediately to prevent further corrosion. Proper storage also plays a critical role. Keep the mesh in a dry place to reduce moisture exposure. Avoid stacking heavy items on it, as this can cause distortion.

Sometimes, despite best efforts, issues arise. It's essential to learn from these moments. We all make mistakes. A damaged mesh might become a lesson for better care practices in the future. Taking these simple steps ensures your woven wire mesh remains effective and visually appealing for years to come.